Lihlahisoa

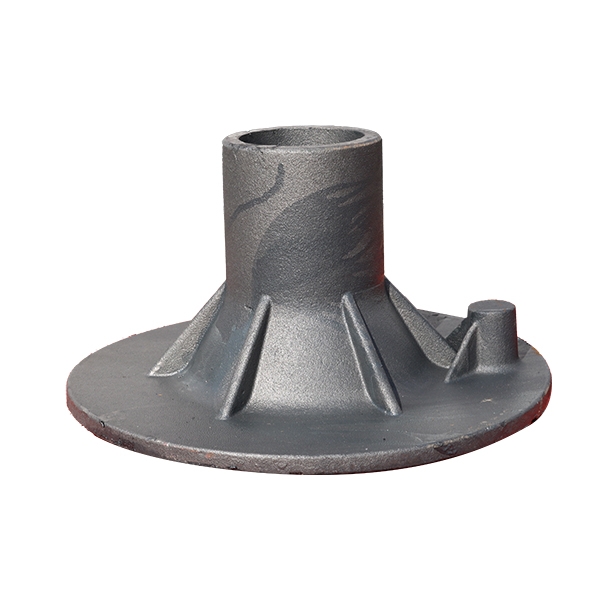

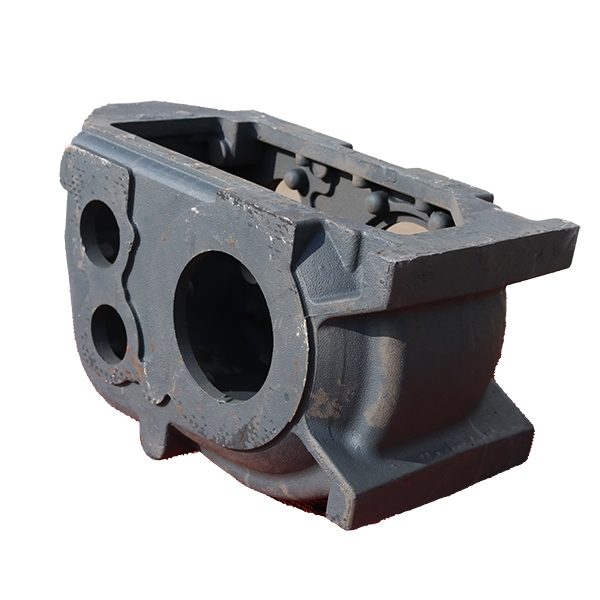

D6-2401001 gearbox Hood

Tšobotsi ea sehlahisoa

Ho lahla foam ho lahla (ho tsejoa hape e le semelo sa 'nete Ka vaerating e khahlehang (e matlafalitsoeng), e boreleli ebile e phefumoloha) le e omileng, e patoa lehlabatheng le qhibilihileng le ho opeloa ke mohlala o omileng. Tšepe e qhibilihileng e tšoloha ka lebokoseng le hlorisoang ke lehlabathe tlasa khatello e mpe, e le hore mohlala oa polymit o futhumatsoa le o hlatsuoa. Mokhoa o mocha oa ho lahla o sebelisang tšepe ea metsi ho nka sebaka sa ho theola boima ba nako e le 'ngoe e entsoeng ka ho futhumatsa le ho khotsofatsa ho hlahisa likhakanyo. Ho lahla foam ho lahlehile ho na le litšobotsi tse latelang: 1. Ho lelekisa lintho ka mokhoa o nepahetseng le litšenyehelo tse tlase; 2. Lisebelisoa ha li felle feela 'me li loketse boholo bohle; 3. Ho nepahala ho phahameng, bokaholimo bo boreleli, bo se ke ba hloekisa le ho ikoetlisa. 4. Bofokoli ba kahare bo fokotsehile haholo mme sebopeho sa ho lahla se ntlafalitsoe. Litekanyo; 5. E ka bona boholo bo boholo le tlhahiso e le 'ngoe; 6. E loketse tlhahiso e ngata ea ho lelekoa ka bongata. 7. E loketse ts'ebetso ea matsoho le tlhahiso ea mehala ea Kopano le taolo ea Kopano le ts'ebetso ea ts'ebetso; 8. Boemo ba tlhahiso ea mohala oa tlhahiso bo kopana le litlhokahalo tsa ts'ireletso ea tikoloho ea tikoloho. ; 9. Ho ka ntlafatsa tikoloho e sebetsang le maemo a tlhahiso a motsamao oa tlhahiso, o fokotsa matla a basebetsi, le ho fokotsa tšebeliso ea matla.

Tlhaloso ea Sehlahisoa

Ho lahla foam ho lahla (ho tsejoa hape e le semelo sa 'nete Ka vaerating e khahlehang (e matlafalitsoeng), e boreleli ebile e phefumoloha) le e omileng, e patoa lehlabatheng le qhibilihileng le ho opeloa ke mohlala o omileng. Tšepe e qhibilihileng e tšoloha ka lebokoseng le hlorisoang ke lehlabathe tlasa khatello e mpe, e le hore mohlala oa polymit o futhumatsoa le o hlatsuoa. Mokhoa o mocha oa ho lahla o sebelisang tšepe ea metsi ho nka sebaka sa ho theola boima ba nako e le 'ngoe e entsoeng ka ho futhumatsa le ho khotsofatsa ho hlahisa likhakanyo.

Ho lahla foam ho lahlehile ho na le litšobotsi tse latelang: 1. Ho lelekisa lintho ka mokhoa o nepahetseng le litšenyehelo tse tlase; 2. Lisebelisoa ha li felle feela 'me li loketse boholo bohle; 3. Ho nepahala ho phahameng, bokaholimo bo boreleli, bo se ke ba hloekisa le ho ikoetlisa. 4. Bofokoli ba kahare bo fokotsehile haholo mme sebopeho sa ho lahla se ntlafalitsoe. Litekanyo; 5. E ka bona boholo bo boholo le tlhahiso e le 'ngoe; 6. E loketse tlhahiso e ngata ea ho lelekoa ka bongata. 7. E loketse ts'ebetso ea matsoho le tlhahiso ea mehala ea Kopano le taolo ea Kopano le ts'ebetso ea ts'ebetso; 8. Boemo ba tlhahiso ea mohala oa tlhahiso bo kopana le litlhokahalo tsa ts'ireletso ea tikoloho ea tikoloho. ; 9. Ho ka ntlafatsa tikoloho e sebetsang le maemo a tlhahiso a motsamao oa tlhahiso, o fokotsa matla a basebetsi, le ho fokotsa tšebeliso ea matla.

U batla ho bua ka seo re ka u etsetsang sona?

Lekola tharollo ea rona e ka u nka.