Lihlahisoa

EPTS110 Mothusi

Tšobotsi ea sehlahisoa

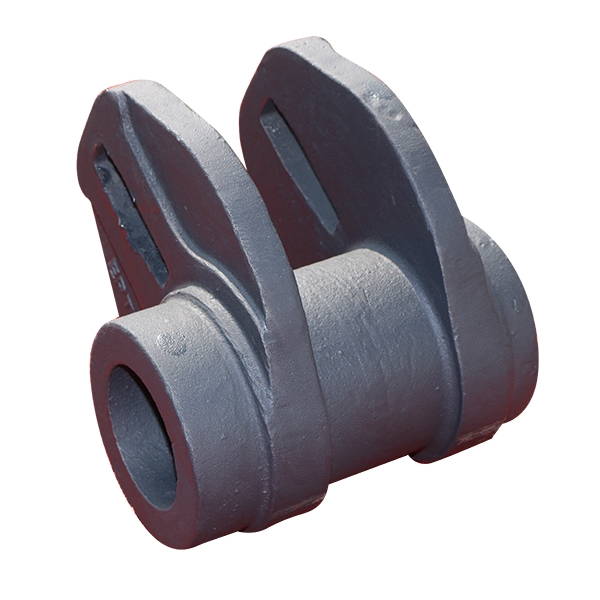

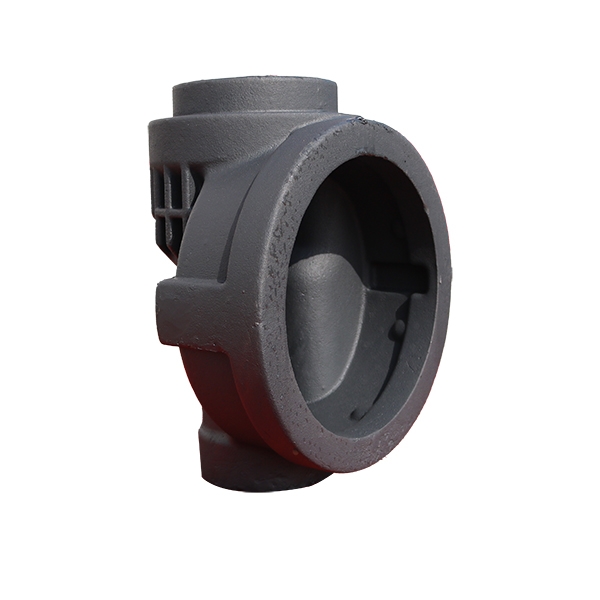

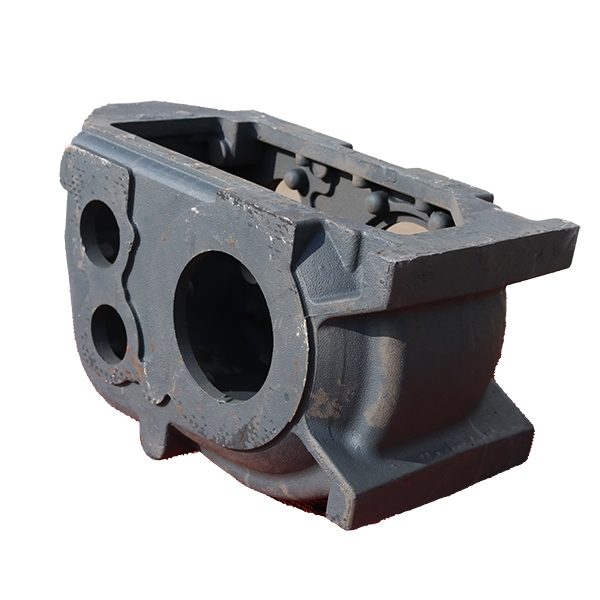

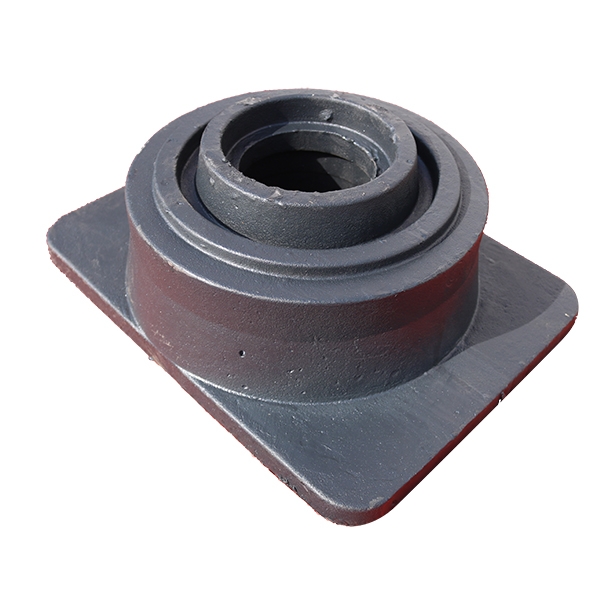

Ho lahla foam ho lahla (ho tsejoa hape e le semelo sa 'nete Ka vaerating e khahlehang (e matlafalitsoeng), e boreleli ebile e phefumoloha) le e omileng, e patoa lehlabatheng le qhibilihileng le ho opeloa ke mohlala o omileng. Tšepe e qhibilihileng e tšoloha ka lebokoseng le hlorisoang ke lehlabathe tlasa khatello e mpe, e le hore mohlala oa polymit o futhumatsoa le o hlatsuoa. Mokhoa o mocha oa ho lahla o sebelisang tšepe ea metsi ho nka sebaka sa ho theola boima ba nako e le 'ngoe e entsoeng ka ho futhumatsa le ho khotsofatsa ho hlahisa likhakanyo. Ho lahla foam ho lahlehile ho na le litšobotsi tse latelang: 1. Ho lelekisa lintho ka mokhoa o nepahetseng le litšenyehelo tse tlase; 2. Lisebelisoa ha li felle feela 'me li loketse boholo bohle; 3. Ho nepahala ho phahameng, bokaholimo bo boreleli, bo se ke ba hloekisa le ho ikoetlisa. 4. Bofokoli ba kahare bo fokotsehile haholo mme sebopeho sa ho lahla se ntlafalitsoe. Litekanyo; 5. E ka bona boholo bo boholo le tlhahiso e le 'ngoe; 6. E loketse tlhahiso e ngata ea ho lelekoa ka bongata. 7. E loketse ts'ebetso ea matsoho le tlhahiso ea mehala ea Kopano le taolo ea Kopano le ts'ebetso ea ts'ebetso; 8. Boemo ba tlhahiso ea mohala oa tlhahiso bo kopana le litlhokahalo tsa ts'ireletso ea tikoloho ea tikoloho. ; 9. Ho ka ntlafatsa tikoloho e sebetsang le maemo a tlhahiso a motsamao oa tlhahiso, o fokotsa matla a basebetsi, le ho fokotsa tšebeliso ea matla.

Tlhaloso ea Sehlahisoa

Theknoloji ea Floam e lahlehileng ke ho kopanya mefuta ea likhukhung le ho kopanya mefuta ea litlolo tse tšoanang ka boholo le sebopeho ho litsoi ho ea ho lihlopha tsa Mohloli. Kamora ho hlatsoa ka ho koahela ka ho pheta le ho omella, ba patoa lehlabatheng le omileng 'me ba silafalitsoe ke sebopeho, le tšepe ea metsi e tšeloa tlasa maemo a itseng. , mokhoa oa ho lelekeloa ke mohlala mme o lula boemong ba mohlala, o tiisa le ho futhumatsa ho etsa hore e be le lelekisang. Ho na le mabitso a mangata a fapaneng bakeng sa ho lahla foam. Mabitso a mantlha a lehae a masene a "lahlile callting e tiileng" le "khatello e mpe", e bitsoang e le casetles e tiileng. Ho na le mabitso a kantle ho naha ke afe:

Ha ho bapisoa le theknoloji ea setso, e lahlehileng ea lebese le se nang palo, ka hona e nyopa e le "Phetohelo ea Lits'ebeletso tsa Ntlafatso" ke mekoloko ea lapeng ka lapeng.

U batla ho bua ka seo re ka u etsetsang sona?

Lekola tharollo ea rona e ka u nka.